What is the main features of MP resin (equal to Laroflex MP grade)?

The full name of MP resin is copolymers of vinyl chloride and vinyl isobutyl ether. It is equal to BASF Laroflex MP grade. It is good type of chlorinated binder and developed for printing ink and heavy anticorrosive paint.

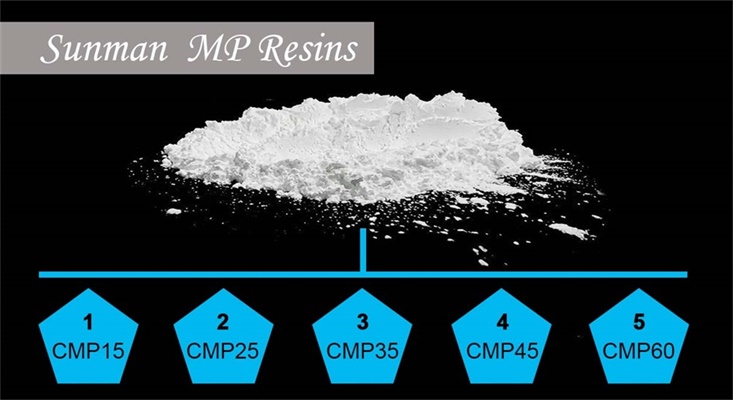

Hereby pls check some of main features about sinosunman MP resin as follows;

1. Good adhesion

They contain copolymer of vinyl chloride ester which ensures paint good adhesion on various material. Even on the surface of aluminum or zinc, the paint still has good adhesion.

2. Good anti-corrosion ability

It offer good bonding property as a result of their special molecular structure, in which ester bond is resistant to hydrolysis and combined chlorine atom very stable. Thus they can be used to produce high quality paint with good water resistance, salt resistance and chemical resistance.

3. Good compatibility

They are compatible with vinyl chloride copolymer, poly-acrylate, unsaturated polyester resin, maleic alkyd resin, cyclohexanone resin, aldehyde resin, coumarone resin, hydrocarbon resin, urea resin, alkyd resin modified by oil and fatty acid, natural resin, plasticizer and bitumen. They can modify and improve the characteristics of paint which is mutated by drying oil, alkyd rein, tars and bitumen.

4. Good stability

No reactive double bond, so resins are not easily being acidized and degraded. The molecules are also with excellent light stability and won’t turn yellow or atomize. The existence of each bond gives the molecule good internal plasticization. So the resins are flexible enough and additional plasticizer is not required. Also they will not gradually crack causing by migration of plasticizer.

5. Solubility

CMP chlorinated resins are soluble in aromatic hydrocarbon, ester, ketone, glycol, ester acetate and some glycol ether. Aliphatic hydrocarbon and alcohol are diluent and not true solvents for CMP chlorinated resin

Prev: A Beginner's Guide to Using 99% Benzyl Benzoate CAS 120-51-4